原材料: .超纯净不锈钢316L

Principal Component Ratio(mass%)

|

冶炼方式 |

强秦科技超高纯材料化学成分 (*ppm) |

||||||||||||

|

元素 |

C |

Si |

S |

Mn |

P |

Cu |

Cr |

Ni |

Mo |

O* |

N* |

H* |

|

|

SEMI F20 |

≤0.030 |

≤1.00 |

≤0.01 |

≤1.50 |

≤0.045 |

≤0.3 |

16.0~18.0 |

10.0~15.0 |

2.0~3.0 |

/ |

/ |

/ |

|

|

(VIM+VAR) |

QQ316L-Ⅰ |

0.005 |

0.2 |

0.001 |

0.6 |

0.003 |

0.010 |

17.7 |

14.80 |

2.70 |

8 |

30 |

1 |

|

(VOD+VAR) |

QQ316L-Ⅱ |

0.008 |

0.3 |

0.001 |

0.7 |

0.015 |

0.15 |

17.2 |

14.70 |

2.52 |

10 |

60 |

2 |

|

(EAF+VOD+LF) |

QQ316L-Ⅲ |

0.011 |

0.38 |

0.006 |

0.9 |

0.02 |

0.19 |

16.70 |

13.6 |

2.13 |

30 |

120 |

3 |

|

(EAF+VOD) |

QQ316L-Ⅳ |

0.021 |

0.42 |

0.007 |

0.9 |

0.02 |

0.25 |

16.15 |

10.08 |

2.13 |

40 |

150 |

5 |

应用领域:广泛用于半导体产品制造,超高真空阀门装置,过滤器外壳等要求超净性,超低气气体成分的不锈钢。

技术重点:在素材的制造过程中采用VIM+VAR冶炼,降低非金属夹杂和气体成分。

非金属夹渣等级:

|

钢级 |

ASTM-D法(Worst Thin) |

|||||

|

0.5 1.0 1.5 2.0 2.5 (级) |

||||||

|

QQ316L-Ⅰ |

|

|

|

|

|

|

|

QQ316L-Ⅱ |

|

|

|

|

|

|

|

QQ316L-Ⅲ |

|

|

|

|

|

|

|

QQ316L-Ⅳ |

|

|

|

|

|

|

不锈钢EP管/ Stainless Steel EP Pipe

主要钢级/钢号: TP316L控硫(S : 0.005~0.012 )

执行标准: ASTM A269& SEMEI F20-0706E, JIS G3459& SEMI F20-0706E,

SEMI F19-0304 , ASME BPE-2012

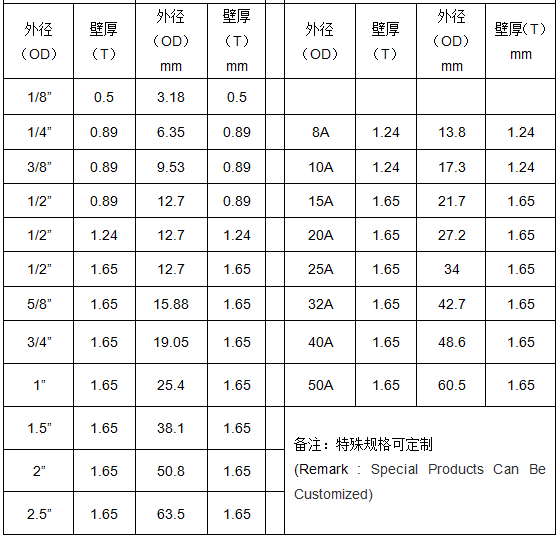

规格表:

1、 BPE级EP管,原材料来自华新丽华、永兴、宝钢、太钢,内壁粗糙度:Ra≦0.25um,洁净清洗,无尘洁净室包装,氮气灌满后每支两头戴管帽,套袋两层包装。(普通气体管路使用) (Ordinary EP Pipe, Raw Material is from YONGXING, Baosteel,TISCO,Inner surface roughness<Ra0.2um,clean washing, package in dust-fress roon,both end with cap, after full with nitrogen gas & each pipe with two plastic bag. (General gas pipeline use.)

2、HP级EP管,原材料进口或者国内真空冶炼,内壁粗糙度:Ra≦0.2um,电解抛光后电解层Cr/Fe大于等于1.5,氧化层厚度大于等于1.5nm,CPT临界点蚀温度大于25℃,电阻率大于等于18兆欧的超纯水清洗,无尘洁净室包装,氮气灌满后每支两头戴管帽,套袋两层包装。(特种气体管路使用) (Clean EP Pipe,raw material is from Import or domestic vacuum metling (VIM),Inner surface roughness<Ra0.2um,Electrolytic layer Cr/Fe ≥1.5 after electrochemical polishing & clean wash, package in dust-fress roon,both end with cap, after full with nitrogen gas & each pipe with two plastic bag. (Special gas pipeline use.)

3、UHP级EP管,原材料进口或者国内真空冶炼,内壁粗糙度:Ra≦0.125um,电解抛光后电解层Cr/Fe大于等于1.5,氧化层厚度大于等于1.5nm,CPT临界点蚀温度大于30℃,电阻率大于等于18兆欧的超纯水清洗,无尘洁净室包装,氮气灌满后每支两头戴管帽,套袋两层包装。(特种高纯腐蚀性气体管路使用) (Ultra-Pure EP Pipe, raw material is from Import or domestic vacuum metling(VIM+VAR), Inner surface roughness<Ra0.15um,Electrolytic layer Cr/Fe ≥1.5 after electrochemical polishing & clean wash, package in dust-fress roon,both end with cap, after full with nitrogen gas & each pipe with two plastic bag. (Special high purity corrosive gas pipeline use.)